Why undertake a thermographic survey?

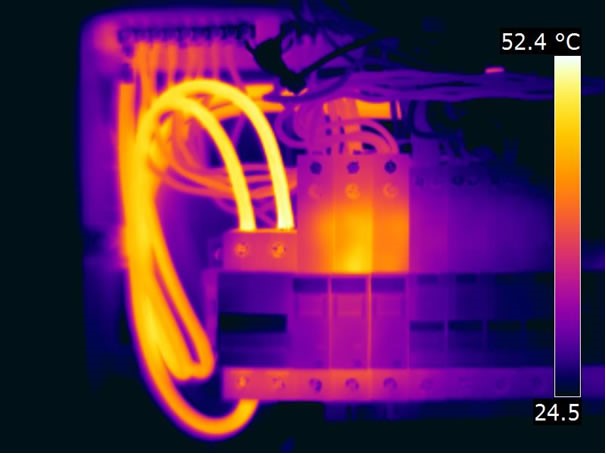

Thermography is a long established technology that has found many uses particularly with planned or preventative maintenance.

It’s great benefit is that thermography is at its best when the surveyed item is operating under normal conditions which in turn negates the need to have disruptive isolations causing inconvenience to the workforce or building user.

When is it best used?

The best use of thermography is to provide an interim non-disruptive inspection of the electrical and mechanical installation.

The Institute of Electrical Engineers (IEE) recommend routine inspections to the electrical installation between the formal periodic inspections. Thermography is a great way to satisfy this requirement due to its non-disruptive nature.

What can be surveyed?

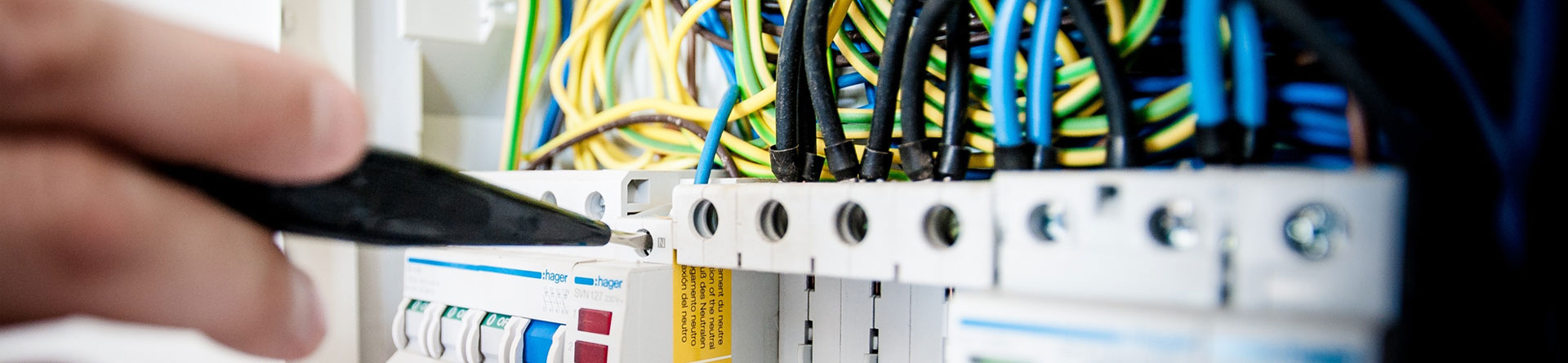

All aspects of the electrical installation can be surveyed and DLM can provide you with expert guidance in making this decision.

Typical items that would be incorporated within a survey would be;

- Electrical Distribution Boards and Main Panel Boards

- Cable Runs & Terminations

- Power Busbars, electrical risers and tap off units

- Heating, Ventilation and Air Conditioning Panels

- Motors and Pumps

- Critical or essential power

- External power supplies such as generators, Combined heating power (CHP) & UPS

Are there any other benefits from a survey?

Typically when undertaking any inspection safety is quite often the main objective. However, many electrical installations require a higher integrity for the continuity of supply to maintain business critical services.

Though the installations may have undergone a thorough periodic inspection, frequently isolation of the critical parts will not be permitted to be inspected by the client due to the disruption it may cause. A thermographic survey of those parts of the installation maybe vital in identifying latent defects which in turn could lead to failure of the electrical supply.

Here at DLM we Believe Thermal Image surveys are an important part of protecting your installation and proactively recommend there use to anylize the current condition and advise accordingly, they also supplement Electrical Inspection and testing giving you our client visible and reference images.